We offer aluminum 6061 and aluminum 7075 to make versatile aluminum CNC parts. Featuring good machinability, high abrasion resistance, good corrosion resistance, aluminum CNC parts can be widely used in many applications. Various surface finishing options are available for aluminum CNC parts.

| Material | Maximum Printing Size | Standard Lead Time | Tolerance | Color |

|---|---|---|---|---|

Aluminum 6061 |

1000*1000*600mm | 4 Business Days | 0.025/0.05/0.1 mm | Silver |

Aluminum 7075 |

1000*1000*600mm | 4 Business Days | 0.025/0.05/0.1 mm | Silver |

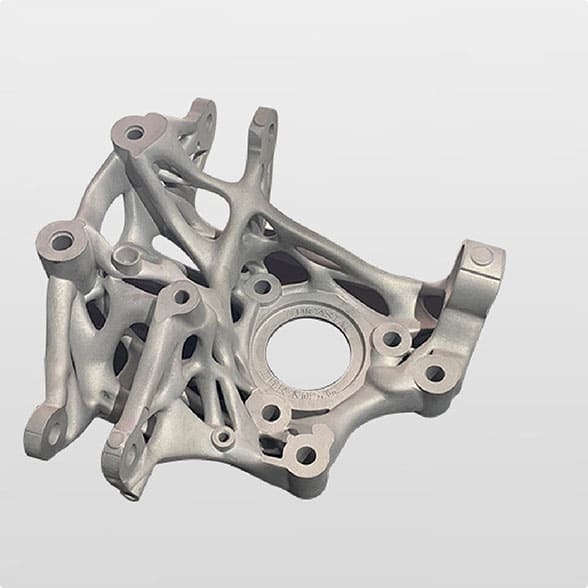

> Automotive Parts

> Aerospace Components

> Industrial Equipment (Housing, Brackets, Fixtures, etc.)

> Consumer Electronics (Panels, Knobs, Enclosures, etc.)

Step 1. Convert the CAD file into a language that CNC machines can work with, that's G-code.

Step 2. The operator will place the aluminum workpiece that is cut to a specific size on the machine bed. Then it is time to mount the aluminum workpiece on the machined bed or by a vice.

Step 3. As the computer controls the CNC cutting tools to move to the pre-set coordinates, so precise positioning and alignment of the aluminum workpiece is significant to manufacture high-accuracy parts. Special metrology tools, probes, for instance, are ideal solutions for this step.

Step 4. Then, the aluminum workpiece is ready for machining. The machine uses professional cutting tools and rotating the at high speeds to remove material from the workpiece. However, at the very first steps, the machine removes at a relatively low speed and accuracy to gain an approximate geometry.

Step 5. Sometimes, the model is not being to achieve full features by single setup from the cutting tools, then to flip the aluminum workpiece is necessary.

1. How much does it cost to CNC machining aluminum parts?

2. What is aluminum CNC machining?

3. What kind of finishes are possible with aluminum CNC machining?

4. Is aluminum CNC parts durable?

5. Will aluminum CNC parts rust?

Aluminium doesn't rust. But please keep in mind that pure aluminum is a highly reactive metal.

From Idea to Products

©2019-2025 WeNext Technology Co., Ltd. All Rights Reserved.

This website uses cookies for better personalized services. By using our websites, you agree to this use. Privacy Policy

We use cookies to improve your experience, check out Privacy Policyy.