What is 3D Printing? How does 3D Printing work? This article introductory knowledge of 3D Printing that you want to know.

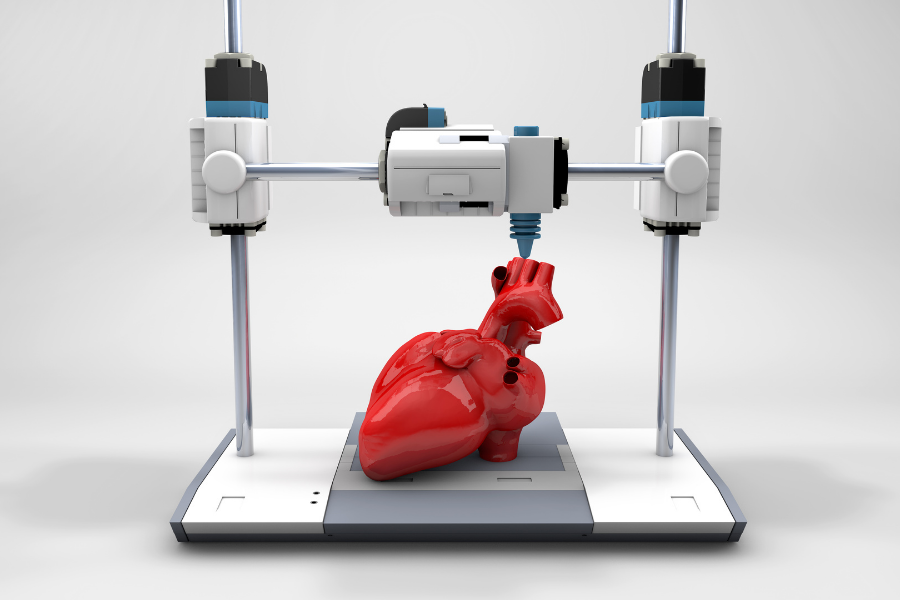

3D Printing, also known as additive manufacturing (AM), is the preferred rapid prototyping method nowadays; utilizing 3D Printing to create custom parts and end-use functional parts is available and accessible. What is 3D Printing? How does 3D Printing work? This article introductory knowledge of 3D Printing that you want to know.

3D printing, also known as three-dimensional printing, additive manufacturing (English: Additive Manufacturing, AM), and cumulative manufacturing, can refer to any process of three-dimensional printing objects. 3D printing is primarily a process of continuously adding and layering raw materials under computer control. The content of 3D printing can be derived from 3D models or other electronic data, and its printed 3D objects can have any shape and geometric features. Three-dimensional printers are a type of industrial robot.

"3D printing" originally meant to deposit materials onto a powder layer inkjet printhead sequentially. Recently the term has been expanded to include a wide range of technologies such as extrusion and sintering processes. Technical standards generally use the term "additive manufacturing" to convey this broad meaning.

3D design

The design process for 3D printing is first to model the model through computer modeling software and then "partition" the completed 3D model into layer-by-layer sections, i.e., slices, which guide the printer to print layer-by-layer.

The standard file format for collaboration between the design software and the printer is the STL file format. An STL file uses triangular surfaces to approximate the surface of an object. PLY is a scanner that generates 3D files by scanning, and the resulting VRML or WRL files are often used as input files for full-color printing.

Slicing

The printer reads the cross-sections from the file, prints them out layer by layer using liquid, powder, or sheet materials, and then bonds the layers together in various ways to create a solid. The special feature of this technology is that it can produce objects of almost any shape.

The thickness (i.e., Z-direction) and the resolution in the planar direction (i.e., X-Y-direction) of the sections produced by the printer are measured in dpi (pixels per inch) or microns. The typical thickness is 100 microns, i.e. 0.1 mm, but some printers such as the ObjetConnex series and the 3D Systems' ProJet series can print in layers as thin as 16 microns. In the flat direction, it is possible to print at a resolution similar to that of a laser printer. The printed 'ink droplets' are typically 50 to 100 microns in diameter. The production of a model by conventional methods usually takes from a few hours to a few days, depending on the size and complexity of the model. With 3D printing, the time can be reduced to a few hours, depending on the printer's performance and the model's size and complexity.

Whereas traditional manufacturing techniques such as injection molding can produce large quantities of polymer products at a low cost, 3D printing can produce relatively small quantities faster, more flexibly, and lower cost. A desktop-sized 3D printer is all a designer or concept development team needs to make a model.

Finishing the print

The resolution of a 3D printer is sufficient for most applications (where curved surfaces can be rough, like jagged teeth on an image), and higher resolution items can be obtained by first producing a slightly larger object with a current 3D printer and then lightly sanding the surface to produce a smooth "high resolution " objects.

Some technologies can print on multiple materials at the same time. Some techniques also use support in the printing process. For example, when printing objects with an upside-down shape, something easily removable (such as a soluble material) is used as a support.

3D printing prototypes can be traced back to the invention of inkjet printers in 1976 until Charles Hoare applied optical technology to the field of rapid prototyping in 1984; the curtain of 3D printing was officially opened, after which many related 3D printing technologies spurted out, according to the characteristics of 3D printing technology, 3D printing technology can be divided into selective laser melting moulding, selective laser sintering moulding, laser Direct sintering technology, electron beam melting technology, fused deposition moulding, selective thermal sintering, three-dimensional lithography, digital light processing, three-dimensional printing technology, and cell mapping printing, etc.

The following is an introduction to the mainstream technology of 3D printing and its process flow, which can help you understand the working principle of 3D printing and its operational characteristics.

1. fused deposition modelling (FMD)

FMD is probably the most widely used process, and many consumer 3D printers use it because it is relatively easy to implement. The material is instantly solidified to form a thin layer with a contoured shape.

This process is very similar to the printing process of 2D printers, except that what comes out of the print head is not ink but molten material such as ABS resin. Because the print head or base of the 3D printer can move in the vertical direction, it allows the material to accumulate rapidly layer by layer. Each layer is a CAD model to determine the trajectory of the printed shape so that the final design of the 3D object can be printed.

2. Light-curing three-dimensional moulding (Stereolithography, SLA)

According to Wikipedia, the first rapid prototyping equipment in 1984 was the light-curing stereolithography process, and now the rapid prototyping equipment, SLA research is the most in-depth use of the most extensive. We usually refer to this process as "light curing, " based on a photosensitive resin that can polymerize under UV light.

As with other 3D printing processes, SLA light-curing equipment slices a 3D digital model of the object before " printing" it. A computer-controlled UV laser then scans the liquid resin point by point along the contours of the part's layered cross-sections. The scanned resin layers polymerize, gradually forming lines from dots and forming a thin cured cross-section of the part. In contrast, the unscanned resin remains in its original liquid state.

When a layer is cured, the lift table is moved one layer thickness away, and a new layer of liquid resin is applied to the surface of the previous layer of cured resin for another scan cure. The newly cured layer is firmly bonded to the previous layer, and so on, until the entire part is prototyped.

The SLA process is characterized by its ability to deliver high precision and good surface quality and produce parts with particularly complex shapes (e.g. hollow parts) and fine details (e.g. crafts, jewellery, etc.).

3、Selective laser sintering (SLS)

Digital model layer-by-layer cutting and layer-by-layer manufacturing is the basis of the 3D printing process and will not be repeated here. In addition, the SLS process and SLA light-curing process have similarities. That is, they both require the use of a laser to cure the material as a whole. The difference is that the SLS process uses an infrared laser beam. The material changes from a photosensitive resin to a powder of plastic, wax, ceramic, metal or a combination thereof.

A thin (sub-millimetre) layer of raw material powder is laid on the workbench, followed by a computer-controlled laser beam scanned by a scanner at a certain speed and energy density in two-dimensional data on a sub-level. The laser-scanned powder is then sintered into a solid sheet layer of a certain thickness, while the unscanned areas remain in a loose powder form. One layer is scanned, and then the next layer is scanned. The table is raised and lowered according to the thickness of the cut-off layer of the object, and the powder laying roller flattens the powder again before starting a new layer of scanning. This is repeated until all layers have been scanned. The excess powder is removed, and the part is obtained after appropriate post-processing, such as grinding and drying.

4、Three-dimensional printing process (3D printing, 3DP) 3DP

Also known as bonded jet, inkjet powder printing. This 3D printing technology works closest to traditional two-dimensional inkjet printing. The same as the SLS process, 3DP technology is also used to make parts by bonding the powder into a whole, but it is not bonded by way of laser melting but through the nozzle-sprayed binder to complete the bonding work.

The nozzle is computer-controlled and runs according to the two-dimensional data of the model cross-section, selectively spraying the binder at the appropriate location to form the final layer. After each layer is bonded, the forming cylinder drops a distance equal to the thickness of the layer, and the powder supply cylinder rises a certain height to push out the excess powder, which is pushed by the powder spreading roller to the forming cylinder, where it is flattened and then compacted. So on and so forth, until the whole object is finished bonding.

(1) Light-curing printer is the thermal transfer of powder to the processing table for assembly to complete the print. The general problem of this method is thermal expansion and low accuracy.

(2) 3d hot melt adhesive, by transferring the digital 3d material to the physical processing table, can form a hot melt elastomer, and hot melt adhesive can be 3d printed. Compared to traditional printing methods, 3d printing is fast and easy and has the advantages of being super cheap and high efficiency.

(3) laser fusion 3d printing is the fastest, most simple and most efficient method. The difficulty of laser fused 3d printing is much lower compared to fused inkjet printing. But it is not high precision, high price.

(4) powder laser fusion 3d printing. This method does not have to transfer the powder or material to the processing table. It directly heats a metal powder, the powder is melted and gathered together, and then it can be printed. The disadvantage of this method is the high cost, and it often has to be in the middle of the row of powder.

(5) 3d printing, which prints from the material used. Its principle is similar to powder laser fusion 3d printing. Still, it can print some conventional materials, such as abs, pla, etc. fdm3d printing is slightly lower in cost, but the accuracy is limited.

With the development of technology and the need to promote its application, the manufacture of functional metal parts using additive manufacturing has become a major development in additive manufacturing. The next section will introduce you to all the technologies available for 3D printing metal parts and which technology you should choose to use to print metal parts.

Currently, there are about 10 methods on the market to 3D print metal parts. These methods are roughly divided according to the form of raw material used and the energy source, such as whether the material is wire, metal powder or metal wire. Some even use metal resin, metal rods and metal pellets as raw materials, with each method producing parts with different properties.

The choice of which metal technology to use requires consideration of part detail, shape, size, strength, metal type, cost, print speed and quantity. When analysed in these terms, each technology has advantages and disadvantages. Unfortunately, no single method can 3D print superb parts quickly, cheaply and perfectly, so it is up to the application requirements to choose exactly which technology to use.

1. FDM vs. extrusion

There are several 3D printing technologies that fall under the category of extrusion. One is the familiar fused deposition moulding (FDM), which uses filaments made from a plastic substrate into which metal particles are uniformly injected. The metal filament used to print the metal part must contain a high percentage of metal powder (around 80%) and needs to undergo post-processing such as degreasing and sintering to remove the plastic component to obtain the metal part. Some desktop FDM 3D printers on the market can print with metal filaments, which are available in stainless steel (316L, 17-4 PH), copper and titanium.

Another technique uses metal filaments with a higher concentration of metal. So much so that it is actually a strong metal rod, but can still be heated and extruded. These materials are usually unique to a particular 3D printer, such as Markforged or Desktop Metal, and cost more than regular FDM but less than other metal 3D printing methods.

The third metal extrusion method (of which there are more in the industrial sector) is extrusion using metal pellets, which can be the same materials as injection moulding, so the material system is more varied and comprehensive and cost-effective, or of course specially made pellets. Such as the domestic sublimation of three-dimensional, which can be based on injection moulded materials for secondary development and adaptation, greatly improving the flexibility of the material, optimising the material properties, which in turn makes the sintered products more dense, increased strength, toughness, improved ductility, electrical and thermal conductivity, magnetic properties.

2. Metal powder bed melting using lasers - selective laser melting (SLM)

3D printers that use high power lasers to selectively melt metal powders, a technology that makes up the majority of metal 3D printers, are often referred to as selective laser melting (SLM) or powder bed melting (PBF). The printers can use "pure" metal materials or alloyed materials.

SLM 3D printers use a powdered metal raw material, which is flattened by a squeegee or roller onto a substrate or build platform to form a thin layer after being fed into the print bin. Next, a high powered laser selectively melts the powdered material following a pattern of slices. The build plate is then lowered to the height of a small layer and the coater lays another new layer of powder on the surface. The printer repeats these steps until the finished part is obtained.

Compared to EBM technology, SLM technology can print with a better initial surface finish and higher precision.

3. Metal powder bed fusion with electron beams - electron beam melting (EBM)

Electron beam melting is a 3D printing technology that uses an electron beam as an energy source, primarily for conductive metals. All EBM 3D printers have an energy source capable of emitting an electron beam, a powder container, a powder feeder, a powder re-coater and a heated build platform. It is important to note that the printing process must occur in a vacuum. This is because the electrons from the electron beam will collide with gas molecules, which will "kill" the electron beam. Due to the higher energy of the electron beam, EBM can be faster than SLM, and the residual stress on the product part is lower than SLM.

4. Metal binder jetting

Metal binder jetting can print parts with complex designs that are not solid, and the resulting parts have the same strength while being significantly lighter. The porous nature of binder jetting can also be used to achieve lighter-end parts for medical applications, such as implants. As with other additive manufacturing processes, binder jetting can produce complex parts with internal channels and structures, eliminating the need for welding and reducing the number and weight of parts. Redesigning your metal parts for binder jetting can significantly reduce the amount of material used and wasted.

Overall, the material properties of metal binder injection parts are comparable to those of metal parts produced by metal injection moulding, which is one of the most widely used manufacturing methods for mass-produced metal parts. In addition, binder-injected parts exhibit a higher surface smoothness, especially in the internal channels.

5. Arc-fed wire additive manufacturing (WAAM)

Arc-fed wire additive manufacturing uses wire as the material and an electric arc as the energy source, similar to welding. The arc melts the wire, deposited layer by a robotic arm onto a forming platform. As with welding, an inert gas is used to prevent oxidation and to improve or control the properties of the metal.

The process gradually creates a complete three-dimensional object out of the material or repairs an existing one. No support structures need to be removed, and the finished part can be CNC machined to tight tolerances or surface polished if necessary. Often, printed parts require heat treatment to relieve residual stresses.

6. Laser-based Directed Energy Deposition (DED)

Laser Directed Energy Deposition is used to melt metallic materials while deposited by a nozzle. The metallic material can be in the form of powder or wire. Although complete parts can be constructed with DED technology, this technique is often used to repair or add material to existing objects. Combined with CNC machining, it can produce an exact, finished part.

DED systems may differ from PBF systems because the powders are usually larger and require a higher energy density. Has a faster build rate compared to PBF systems? However, brings with it poorer surface quality and may require additional machining. Support structures typically used for PBF systems are rarely or never used for DEDs, which typically use a multi-axis rotary table to rotate the build platform to achieve different features. DED systems can be repaired or printed on existing parts where a powder bed is not required.

7. Based on Electron Beam Directed Energy Deposition (DED)

Electron Beam Directed Energy Deposition uses an electron beam to melt metal wires (rather than powder) while being deposited by a nozzle. Similar to WAAM above, electron beam DED is prized for its speed. Unlike WAAM, these printers require a vacuum chamber. Typically, parts are printed to near net shape and then machined to tight tolerances using a CNC machine, as shown in the photo above.

8. Metal Stereolithography

Metal lithography, also known as photolithography-based metal fabrication (LMM), uses a mixture of photosensitive resin and metal powder as the raw material. This light-sensitive paste is selectively polymerised layer by layer in the presence of light. Metal stereolithography has excellent surface quality and is mostly used for micro 3D printing, so it has great detail.

9. Cold spraying

Cold spraying is a manufacturing technique in which metal powders are sprayed at supersonic speeds and bonded without melting, which creates almost no thermal stress. It has been a coating process since the beginning of the 21st century. Still, recently several companies have used cold spray technology for additive manufacturing because of its ability to apply layers of metal down to a few centimetres precisely at speeds about 50 to 100 times higher than typical metal 3D printers.

In additive manufacturing, cold spray is used for the rapid manufacture of metal replacement parts and the in-situ repair and restoration of metal parts, such as military equipment and machinery for the oil and gas industry. Repaired parts can, in some cases, be better than new.

10. Micro and nano metal 3D printing

There are two ways to make micro-metal 3D printed parts: metal stereolithography, mentioned above, and micro-nano selective laser sintering (SLS), a small-scale laser powder bed melting technique, also mentioned above. Also known as micro laser sintering or microlaser melting, this industrial technique uses a bed of powder and a fine laser.

(1)ABS plastic type

ABS is the most commonly used printing material for FDM and is currently available in various colours. And is the most popular printing material for consumer 3D printer users, such as printing "Lego" type toys, making many creative home accessories, etc. ABS material is usually a fine wire coil printed by heating and melting the 3D printing nozzle. As the nozzle needs to be solidified immediately after spraying, the temperature of the nozzle is controlled to be 1 to 2°C above the melting point of the ABS material. As different ABS have different melting points, it is impossible to match the nozzle with a nozzle that cannot be adjusted for temperature. This is why it is best to buy the printing material from the original manufacturer.

(2) PLA plastic class

PLA plastic fusing wire is also a very common printing material. Especially for consumer-grade 3D printers, PLA is biodegradable and is an environmentally friendly material. PLA generally does not require a heated bed, unlike ABS, so PLA is easy to use and is more suitable for lower-end 3D printers. PLA is available in multiple colours and translucent red, blue, green and fully transparent materials. the versatility of PLA has yet to be improved.

(3) Acrylic materials

Acrylic from the English acrylic, meaning the organic compound methyl methacrylate monomer (Methyl Methacrylate, MMA) made of PMMA plate, its transparency and clarity as glass. All sheets made from transparent plastics (e.g. PS, PC, etc.) or poorly recycled MMA are collectively referred to as Plexiglas. The acrylic (Plexiglas) material has a good surface finish and can be printed in transparent and translucent products. Currently, it is possible to print models of teeth for orthodontic treatment using acrylic.

The development of manufacturing methods has undergone three stages: equilateral, reduced material, and additive manufacturing.

(1) Isomaterial manufacturing refers to producing manufactured products by casting, forging and welding, with the weight of the material unchanged, and has a history of more than 3,000 years.

(2) Reduced material manufacturing, which refers to the use of equipment such as turning, milling, planing and grinding to cut and process materials to achieve the designed shape after the industrial revolution, has a history of over 300 years.

(3) Additive manufacturing, also known as 3D printing, refers to the accumulation of materials bit by bit to form the desired shape through techniques such as light curing, selective laser sintering and melt stacking.

Whether it is material or subtractive, the product's design will be affected and limited by the manufacturing process in the industrial manufacturing process. The designer cannot let go of his imagination as he wishes to pursue an ideal product effect. With the perfect combination of 3d printing technology and traditional processes, industrial manufacturing has become increasingly simple and efficient; for additive manufacturing, any product data can be realised by employing 3D printing, bringing revolutionary changes to the industrial manufacturing sector.

Manufacturing methods have undergone three stages: equilateral, reduced material, and additive manufacturing.

(1) Isomaterial manufacturing refers to producing manufactured products by casting, forging and welding, with the weight of the material unchanged, and has a history of more than 3,000 years.

(2) Reduced material manufacturing, which refers to the use of equipment such as turning, milling, planing and grinding to cut and process materials to achieve the designed shape after the industrial revolution, has a history of over 300 years.

(3) Additive manufacturing, also known as 3D printing, refers to the accumulation of materials bit by bit to form the desired shape through techniques such as light curing, selective laser sintering and melt stacking.

Whether it is material or subtractive, the product's design will be affected and limited by the manufacturing process in the industrial manufacturing process. The designer cannot let go of his imagination as he wishes to pursue an ideal product effect. With the perfect combination of 3d printing technology and traditional processes, industrial manufacturing has become increasingly simple and efficient; for additive manufacturing, any product data can be realised by employing 3D printing, bringing revolutionary changes to the industrial manufacturing sector.

Image Source: futurelearn

Please feel free to try instant quoting on our website or contact us hello@wenext.com if you are interested.

WeNext collaborated with LiYi Bionics, utilizing 3D printing technology as the core manufacturing method, to pioneer a new paradigm for the development and mass production of mechanical bionic hands.

WeNext systematically elaborates on the relevant performance characteristics of Future PA11Pro, shares the material's application in 3D printing, and compares its performance differences with PA12 material, providing a reference for printing material selection and development applications.

WeNext's new generation of FDM materials are continuously being launched. Industrial-grade FDM printing production solutions effectively assist manufacturing across various industries in achieving performance breakthroughs and functional integration.

How to build a movie camera yourself using 3D printing technology? How to perfectly replicate model car parts? WeNext, the great assistant for maker enthusiasts, tells you the answer!

WeNext collaborated with LiYi Bionics, utilizing 3D printing technology as the core manufacturing method, to pioneer a new paradigm for the development and mass production of mechanical bionic hands.

WeNext systematically elaborates on the relevant performance characteristics of Future PA11Pro, shares the material's application in 3D printing, and compares its performance differences with PA12 material, providing a reference for printing material selection and development applications.

WeNext's new generation of FDM materials are continuously being launched. Industrial-grade FDM printing production solutions effectively assist manufacturing across various industries in achieving performance breakthroughs and functional integration.

How to build a movie camera yourself using 3D printing technology? How to perfectly replicate model car parts? WeNext, the great assistant for maker enthusiasts, tells you the answer!

3D printing has become a key technological pillar for the new energy vehicle industry to achieve lightweighting, intelligence, and sustainable development, bringing fresh competitiveness to the sector's advancement.

3D printing technology is reshaping the landscape of the cultural and creative industries in application scenarios such as customized cultural product creation, film & TV IP derivative development, and game merchandise production.

3D printing technology has become a key force driving the advancement of manufacturing in the aerospace sector.

Decoding the manufacturing journey of the “Bloom” torch for the 15th National Games, WeNext broke through the bottlenecks of traditional processes through metal 3D printing technology, transforming Macro’s design concept into reality.

Wenext offers one-stop solutions ranging from rapid prototyping to professional-grade part manufacturing, providing efficient, specialized, and easily accessible manufacturing support for education and scientific research

Wenext launches an LCD printing materials application feature, interpreting the unique properties of diverse high-performance printing materials to provide reference for customers in material selection and application for LCD printing.

Wenext and Liyi Bionics join hands and, with 3D printing technology as the core manufacturing approach, create a completely new paradigm for the research, development, and mass production of mechanical bionic hands.

The integration of 3D printing has not only sped up the design process but also introduced unprecedented flexibility and innovation into the automotive industry

©2019-2025 WeNext Technology Co., Ltd. All Rights Reserved.

This website uses cookies for better personalized services. By using our websites, you agree to this use. Privacy Policy

We use cookies to improve your experience, check out Privacy Policyy.