To help beginners understand 3D Printing easily, this article will introduce more!

Speaking of 3D Printing terminologies, there are a lot of acronyms and backronyms for its printing technologies, and they were all mentioned in Part One. To help beginners to understand 3D Printing comprehensively, we will discuss more 3D printer terms and 3D Printing process unusual words in Part Two. Let’s get started!

Image Source: SGS Maine Pointe

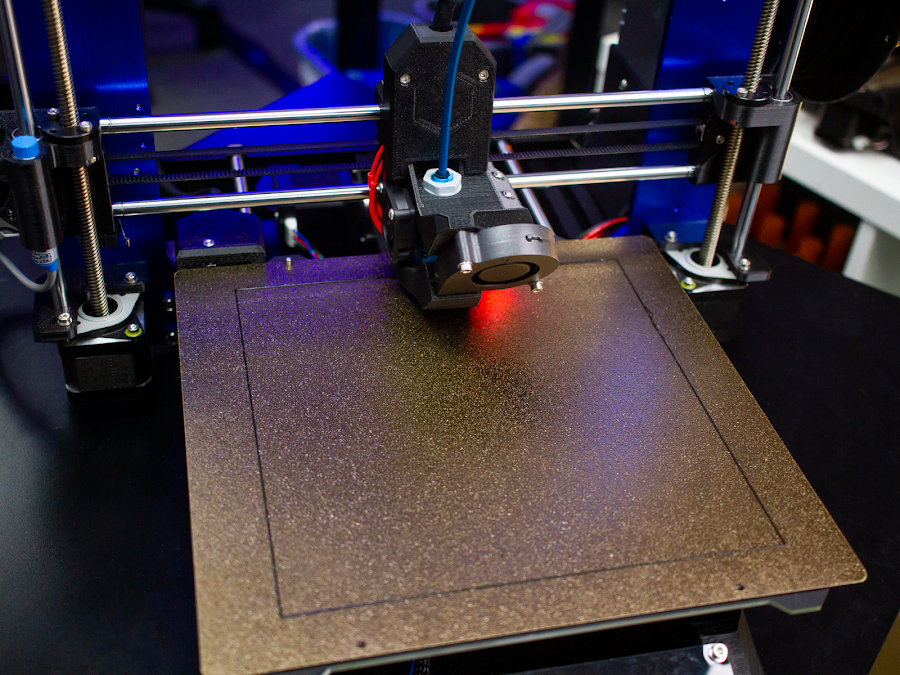

1. Printing Bed/ Build Plate

Printing bed, also called build plate, refers to a place that supports the printed parts in the printing process. Different 3D printing techniques may utilize different build plates. For example, for most resin printers, the printing bed is a single solid part of the printer. When it comes to FDM printer, it is totally another story. Build plate of FDM printer has multiple parts, including heating elements, motion mechanisms, and a flat build surface. Besides, users can customize the build surface by materials, roughness, and size, and users also can add special material on the plate such as glue, tape, and hairspray. All these settings are solutions to ensure a better first surface of the printed part.

Image Source: Matterhackers

2. Build Chamber

As we mentioned that different 3D Printing techniques might have specific unusual words, build chamber is one. Build chamber is the box that contains the printed parts for most powder bed fusing techniques, such as SLS, MJF, and SLM. There are solid parts and un-fused powders inside the build chamber. One specific thing to be noted is that, the build chamber needs time to cool down after printing, and it will send to post-processing with the parts together after cooling down. The un-fused powder in the build chamber can be recycled, while the printed parts need to be removed the excess powder on the surface.

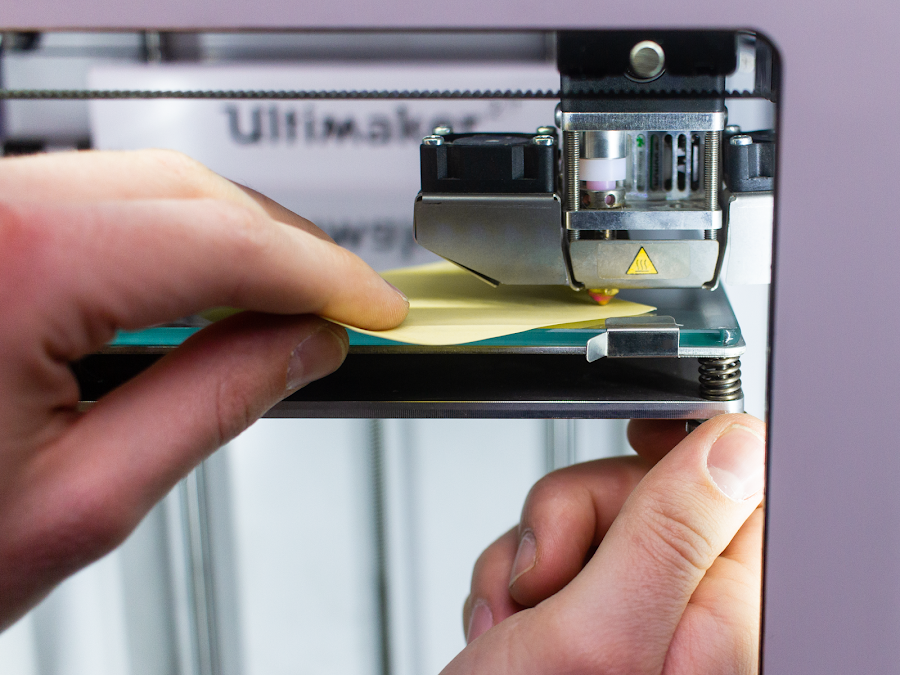

Image Source: Formlabs

3. Bed Leveling

As FDM printers are one of the most popular desktop 3D printers for hobbyists, there are many special settings of the printer figured out by these groups, even the complex part. Bed leveling is one the complex and important part of the FDM workflow. Most people wouldn’t like this step because many printing issues comes from bed leveling settings. So, what is bed leveling exactly? It is relevant to the FDM build plate we’ve mentioned above, which refers to adjusting the build plate to match the nozzle. Users can adjust and level a bed manually, automatically, or with machine assistance. But don’t worry about you can’t handle bed leveling; there are many printers that have automatic bed leveling functions nowadays.

Image Source: Matterhackers

4. Layer Height

Layer height is what it means when you see the word, the height of every printed layer. As 3D printers add materials layer by layer by 3D printers, layer height becomes one of the most important considerations before printing. Many aspects will affect the decision of layer height, including 3D Printing technologies, materials, 3D models, and printer settings. If you pick a high layer height for your model, the layer texture will be more visible, while if you choose a thin one, you will get one with a smoother surface. However, please follow material and printer manufacturing recommendations of minimum layer thickness to ensure that the printed parts are not easily broken or deformed.

Image Source: Slic3r

5. Post-processing

Post-processing is a step of modifying the printed parts after printing. What FDM prints and resin prints need to do first in post-processing is to remove structures. At the same time, resin prints processing is more complicated because it contains multiple steps to get a smooth part with good mechanical properties, such as cleaning and curing. For parts that are made by powders, it needs to be cool down after printing and then sent to remove residual powder on the surface. At wenext, we deliver a wide range of post-processing choices, including sanding, threading, tapping, polishing, grinding, painting, dyeing, etc.

Image Source: MakerBot

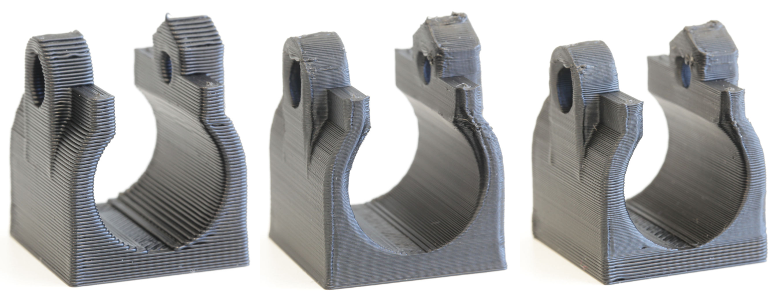

6. Elephant's Foot

There is another common issue of FDM prints, elephant’s foot. The first or first few layers are the foundations of a successful 3D print. So, when the first layer or first few layers are printed wider than expected, it will cause elephant’s foot. It means the part of the area that touched the print bed is outside the expected boundaries as the first layers will gain pressure as the layers are added in the printing process, which may lead to warping. However, there are a few solutions to avoid elephant’s foot, such as releveling the bed, setting a suitable first layer height, adjusting bed temperature, or cooling fans; you can find the right solutions anyway.

Image Source: 3DSOURCED

7. Extruder, Hot End, & Nozzle

Speaking of FDM printers, we have listed several terms, bed leveling, build plate, elephant’s foot, etc. And there are three essential parts that print a solid object they are extruder, hot end, and nozzle. An extruder is a motor with gear that squeeze the filament to the hot end of the printer. While the hot end is where heats and melts the filament. Usually, hot end consists of a throat, heat break, and heat block. The nozzle is the last place that the filament will go. Nozzle absorbs heat from the hot end and reaches high enough temperature to melt the filament, and then the melted filament is squeezed through the hole at the nozzle’s tip and extruded on the build plate.

Image Source: JAKMACHINERY

8. Supports

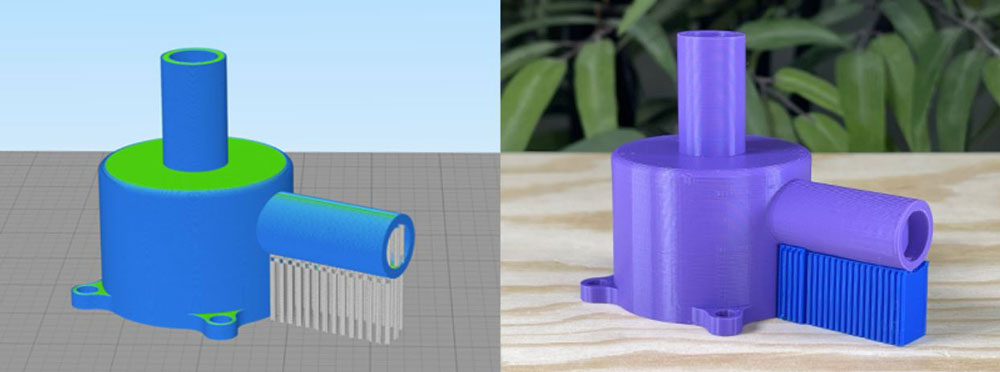

Supports in 3D Printing are parts that support the model to ensure that the model can be printed even with complex structures, allowing overhangs exist. Supports are easy to remove after printing. FDM and resin prints need supports commonly. SLS and MJF are able to print parts with complex geometries without supports as the unfused powder can be supports of the parts. Basically, how much supports will be used depends on the material, model geometries, and 3D printing techniques; however, you can adjust supports by slicer software.

Image Source: SIMPLIFY3D

WeNext collaborated with LiYi Bionics, utilizing 3D printing technology as the core manufacturing method, to pioneer a new paradigm for the development and mass production of mechanical bionic hands.

WeNext systematically elaborates on the relevant performance characteristics of Future PA11Pro, shares the material's application in 3D printing, and compares its performance differences with PA12 material, providing a reference for printing material selection and development applications.

WeNext's new generation of FDM materials are continuously being launched. Industrial-grade FDM printing production solutions effectively assist manufacturing across various industries in achieving performance breakthroughs and functional integration.

How to build a movie camera yourself using 3D printing technology? How to perfectly replicate model car parts? WeNext, the great assistant for maker enthusiasts, tells you the answer!

WeNext collaborated with LiYi Bionics, utilizing 3D printing technology as the core manufacturing method, to pioneer a new paradigm for the development and mass production of mechanical bionic hands.

WeNext systematically elaborates on the relevant performance characteristics of Future PA11Pro, shares the material's application in 3D printing, and compares its performance differences with PA12 material, providing a reference for printing material selection and development applications.

WeNext's new generation of FDM materials are continuously being launched. Industrial-grade FDM printing production solutions effectively assist manufacturing across various industries in achieving performance breakthroughs and functional integration.

How to build a movie camera yourself using 3D printing technology? How to perfectly replicate model car parts? WeNext, the great assistant for maker enthusiasts, tells you the answer!

3D printing has become a key technological pillar for the new energy vehicle industry to achieve lightweighting, intelligence, and sustainable development, bringing fresh competitiveness to the sector's advancement.

3D printing technology is reshaping the landscape of the cultural and creative industries in application scenarios such as customized cultural product creation, film & TV IP derivative development, and game merchandise production.

3D printing technology has become a key force driving the advancement of manufacturing in the aerospace sector.

Decoding the manufacturing journey of the “Bloom” torch for the 15th National Games, WeNext broke through the bottlenecks of traditional processes through metal 3D printing technology, transforming Macro’s design concept into reality.

Wenext offers one-stop solutions ranging from rapid prototyping to professional-grade part manufacturing, providing efficient, specialized, and easily accessible manufacturing support for education and scientific research

Wenext launches an LCD printing materials application feature, interpreting the unique properties of diverse high-performance printing materials to provide reference for customers in material selection and application for LCD printing.

Wenext and Liyi Bionics join hands and, with 3D printing technology as the core manufacturing approach, create a completely new paradigm for the research, development, and mass production of mechanical bionic hands.

The integration of 3D printing has not only sped up the design process but also introduced unprecedented flexibility and innovation into the automotive industry

©2019-2025 WeNext Technology Co., Ltd. All Rights Reserved.

This website uses cookies for better personalized services. By using our websites, you agree to this use. Privacy Policy

We use cookies to improve your experience, check out Privacy Policyy.