Select the right CNC materials to create strong and durable parts, and improve your project progress efficiently.

Choosing the right CNC materials for your product is significant for optimal outcomes. As there are many materials for CNC machining, you may select the materials depending on what applications the product will be utilized. So, in this article we will introduce some common CNC metals and CNC plastics, and provide key considerations when selecting the materials.

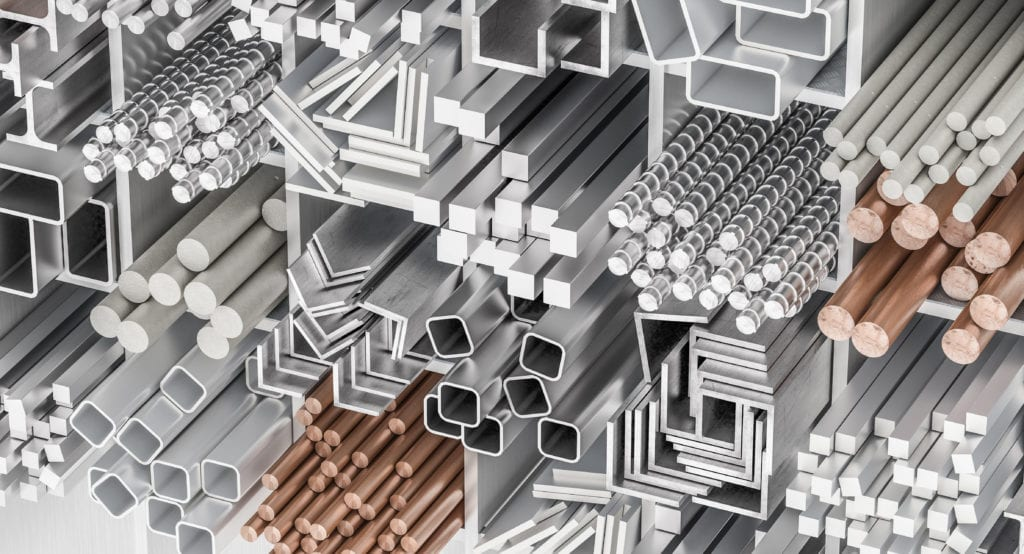

1. Metals

Metals are the main materials in CNC machining, and they have extensive range. Usually, we will consider hardness, strength, and thermal resistance when selecting CNC metals.

Aluminum

Aluminum alloys is highly suitable for light-weight designs with its excellent strength-to-weight ratio. Compared with steel, aluminum has lower strength and hardness, but adding a protective layer through anodizing, aluminum parts can have high strength and corrosion resistance. Aluminum is easy to machine and it is a cost-effective for mass production. CNC milled aluminum alloys can be used in aerospace, automobile, medical industry, and consumer electronics industry, etc.

Steel

A variety of steel alloys are available and accessible for CNC machining. If the part requires higher formability and stronger welds, such as gears, shafts, or some high stress applications, steel alloys can be the option. Stainless steel, mild steel, alloy steel, and tool steel are the main types of CNC steels. When the part needs high strength, high ductility, excellent wear and corrosion resistance, stainless steel is highly recommended. Besides, stainless steel has great machinability and it is easily welded and polished. When cost plays an important role and the application is for general purpose, mild steel (low carbon steel) is suitable. Mild steel also has good weldability, and corrosion resistance. When you consider higher hardness, greater stiffness, and thermal resistance, alloy steel and too steel are exceptional.

Brass

Brass is one of the most economical CNC milled materials. It has good machinability, excellent electrical conductivity, making it ideal for low friction applications. Brass is commonly used for medical equipment, electronic hardware, engineering, plumbing, etc. But brass lacks in strength.

Titanium

Titanium is the biocompatible CNC milling material with extreme high heat resistance. Featuring light-weight and corrosion resistance, titanium is also not compromising strength and stiffness. It is the ideal material for medical implants, aircraft parts, and jewelry.

Cooper

Cooper delivers great electric conductivity, high corrosion resistance and thermal conductivity. It is commonly utilized in automobile applications, such as cooling systems and heat exchangers, as well as various engineering applications like valves and radiators. Cooper is easy to suffer chemical damage, please keep it away from chemicals like acids and ammonia solutions.

Image Source: Weerg.

2. Plastics

Plastics are the other solution when the product requires lightweight design, chemical resistance, and electrical insulation.

ABS

ABS, also known as acrylonitrile butadiene styrene is a common thermoplastic polymer, featuring good mechanical properties, good machinability, and high temperature resistance.

CNC ABS parts are usually used as prototypes before mass-production with injection molding.

PEEK

PEEK is another high-performance engineering thermoplastic that provides great machinability. It has excellent dimensional stability, good chemical resistance, and impact strength, making is the ideal material to replace metals sometimes. Applications include test sockets, switches, connectors, etc. Medical grade PEEK is also available, which makes PEEK is suitable for biomedical applications.

Nylon

Nylon is a thermoplastic that is easy to machine. With excellent mechanical properties, good impact strength, and high chemical and abrasion resistance, it is usually used for bearings and insulators. Nylon 6 and nylon 66 are the most commonly used nylon in CNC machining. Nylon tends to absorb moisture, so, it should be taken good care in storage.

PVC

PVC is an excellent material for CNC machining by its exceptional resistance to chemicals, corrosion, and even flame. It is affordable and easy to access, which makes it an economical solution for different applications.

POM

POM, an engineering thermoplastic, features high machinability and great dimensional stability. While the material has low water absorption. POM is suitable for making CNC plastic parts that require high precision, high stiffness, low friction.

Image Source: B&Z MANUFACTURING

1. What are the overall project costs?

The higher the material performance the part requires, the higher the project costs. Materials with high strength, great machinability, high precision are often expensive. The recommended solution is to select the cost-effective material that suits the part specifications. Choosing the best is not always the best method, what we need to do is to figure out what is the most suitable material for the product. So, focusing on the key elements that the part requires is on top priority.

Image Source: EMC PRECISION

2. What are the using scenarios?

As some materials are easy to damage by chemicals and heat, while some materials tend to absorb moisture which leads to break when it exposes to water, it is necessary to understand the using scenarios entirely. Besides, using indoor or outdoor; and if the parts need to assemble need to be considered. Therefore, it is vital to think over using scenarios or applications before deciding which material to utilize.

Image Source: FAST RADIUS

3. What are material attributes required?

As mentioned above, many materials can be machined with CNC machining. We’ve listed the common CNC metals and CNC plastics, while there are other materials can be made by CNC machining too, like wood and even foam. Different materials feature vibrant attributes and performance, for example, aluminum alloys. There are serval aluminum alloys, such as aluminum 6061, aluminum 7075, aluminum 6082, and aluminum 5083. When you are looking for lightweight designed parts through aluminum, and expecting the part to be stiff, durable, and corrosion resistance, the suitable aluminum would be aluminum 7075. Through heat treatment, the performance aluminum 7075 is comparable to steels.

Have you considered that you can get instant quotation through online CNC machining services? Wenext provides online and on-demand CNC machining services worldwide. With massive in-house manufacturing capabilities (3-axis, 4-axis, and 5-axis machining), we are able to deliver high quality CNC parts in short lead time. We produce parts with tight tolerance that perfectly fit the specifications as designed. Robotics, aerospace, race car, etc., are the high-end industries using our CNC machining services.

Besides, we offer a wide range of CNC materials to our customers, while our Customer Success Manager can share professional advices on material choices, design file checking, and production solutions, to ensure that your project works smoothly. Email hello@wenext.com for more information on CNC Milling, CNC Turning, and CNC materials.

3D printing has become a key technological pillar for the new energy vehicle industry to achieve lightweighting, intelligence, and sustainable development, bringing fresh competitiveness to the sector's advancement.

3D printing technology is reshaping the landscape of the cultural and creative industries in application scenarios such as customized cultural product creation, film & TV IP derivative development, and game merchandise production.

3D printing technology has become a key force driving the advancement of manufacturing in the aerospace sector.

Decoding the manufacturing journey of the “Bloom” torch for the 15th National Games, WeNext broke through the bottlenecks of traditional processes through metal 3D printing technology, transforming Macro’s design concept into reality.

3D printing has become a key technological pillar for the new energy vehicle industry to achieve lightweighting, intelligence, and sustainable development, bringing fresh competitiveness to the sector's advancement.

3D printing technology is reshaping the landscape of the cultural and creative industries in application scenarios such as customized cultural product creation, film & TV IP derivative development, and game merchandise production.

3D printing technology has become a key force driving the advancement of manufacturing in the aerospace sector.

Decoding the manufacturing journey of the “Bloom” torch for the 15th National Games, WeNext broke through the bottlenecks of traditional processes through metal 3D printing technology, transforming Macro’s design concept into reality.

Wenext offers one-stop solutions ranging from rapid prototyping to professional-grade part manufacturing, providing efficient, specialized, and easily accessible manufacturing support for education and scientific research

Wenext launches an LCD printing materials application feature, interpreting the unique properties of diverse high-performance printing materials to provide reference for customers in material selection and application for LCD printing.

Wenext and Liyi Bionics join hands and, with 3D printing technology as the core manufacturing approach, create a completely new paradigm for the research, development, and mass production of mechanical bionic hands.

The integration of 3D printing has not only sped up the design process but also introduced unprecedented flexibility and innovation into the automotive industry

With its unique advantages, SLM metal 3D printing has emerged as a solution for manufacturing intricate metal structural components.

New materials and new technology make 3D Printing silicone possible now! Discover more in this article!

See what toys you can 3D print for your cats, check out the best 3D printed cat toys of 2023 here.

Want to make 3D printed jewelry for yourself or gain inspirations from jewelry 3D models? Check these jewelry STL files out!

©2019-2025 WeNext Technology Co., Ltd. All Rights Reserved.

This website uses cookies for better personalized services. By using our websites, you agree to this use. Privacy Policy

We use cookies to improve your experience, check out Privacy Policy.