To decide whether 3D Printing or CNC machining is the best way for production, in this article we will compare these two manufacturing technologies.

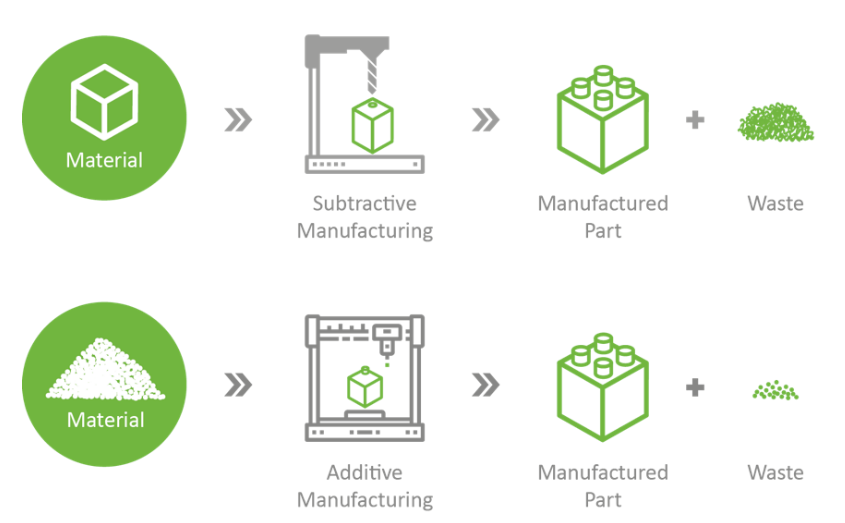

In manufacturing techniques, it is no doubt that 3D Printing is the most popular additive manufacturing (AM) technology in the industry. As 3D Printing is growing rapidly in recent years and it has many advantages over traditional manufacturing methods. However, 3D Printing is not perfect as it is not effective for mass production because of its limitations on accessibility and manufacturing speed. While in low-to-medium production, CNC machining, also known as computer numerical control, is a subtractive manufacturing method that machines workpiece or blank by CNC machines. Therefore, to decide whether 3D Printing or CNC machining is the best way for production, in this article we will compare these two manufacturing technologies.

Image Source: ADVANCED ADDITIVE MANUFACTURING

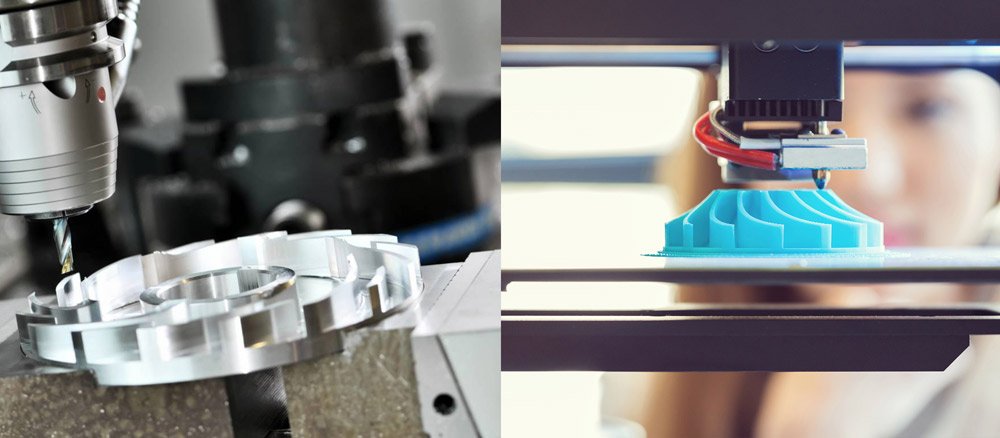

As a subtractive manufacturing technique, CNC machining is a process of machining a block of material (workpiece or blank). To creating final parts with CNC machining, cutters and spinning tools are used. CNC milling and CNC turning are the main types of CNC, and sometimes we take CNC milling equal as CNC machining as it is the most widely used technology. CNC machining is being able to produce parts with complex geometries and tight tolerance, and compatible with multiple materials, including metals, plastics, and wood.

While 3D Printing belongs to additive manufacturing is a way of creating solid parts by adding materials layer by layer based on 3D models. The common materials of 3D Printing includes filaments, liquid resins, plastic and metal powders. In terms of different kind of filaments, it is FDM that prints filaments and it is one of the most popular 3D Printing techniques for hobbyists. Besides, SLA/ DLP/ LCD uses UV-laser to cure liquid resins layer by layer; SLS/ MJF/ DMLS/ SLM are powder bed fused 3D printing, utilizing high-energy laser to fuse or melt powders. 3D Printing can create parts with various shapes freely, even some parts with complex geometries. Many high-end applications including aerospace, automobile, and robotics, etc.

However, with the development of manufacturing technologies, materials, and machines, a few innovative machines integrate 3D Printing and CNC milling capabilities, ZMorph 2.0 SX, for instance. It is a major step in manufacturing industry by combining advantages of different manufacturing methods, and providing more versatile solution to making parts effectively and efficiently.

Knowing the key differences between 3D Printing and CNC machining would be the first step to choose which one is the right manufacturing process for you. So, in the next section, we will discuss manufacturing considerations for both CNC machining and 3D Printing.

Image Source: WISCONSIN METAL TECH

1. Material

Both 3D Printing and CNC machining use a variety of materials, plastics and metals are two main types.

Plastics are still the main material of 3D Printing even though metal 3D Printing is growing rapidly in recent years and there are many online metal 3D Printing services. The commonly used thermoplastics of 3D Printing are PLA, Nylon, ABS, ULTEM, while photo-polymers (wax, liquid resins) are also popular. Metals such as aluminum, stainless steel, and titanium are widely used in 3D Printing. Moreover, some innovative materials like ceramics are emerging in the industry. There are some flexible materials or superalloys are compatible with 3D Printing technology, but CNC cannot make parts with them.

CNC supports plastics including Polycarbonate (PC), Acrylic (PMMA), Polypropylene (PP), POM, PEEK, ABS, and Nylon (PA66). While aluminum is the most common metal of CNC machining. Besides, stainless steel, magnesium alloy, zinc alloy titanium, and brass are common metals in CNC as well.

Image Source: WAYKEN RAPID MANUFACTURING

2. Physical Considerations

Tolerance

Both 3D Printing and CNC machining produce parts with high accuracy, but CNC machined parts have tighter tolerance than 3D printed parts. Nevertheless, tolerance may be affected by machines, material, and model geometries.

Surface Finish

CNC machines are superior to create parts with smoother and glossy surface finish if using the right tools. While parts made by 3D printer may need extra steps to generate smooth surface.

Size

Part sizes of CNC and 3D Printing are limited by tool size. In terms of CNC, tool diameter decides the smallest negative feature. In case of 3D Printing, the printing volume dictates the maximum printing size. Well, part size also limited by model geometries.

Temperature

The way that 3D Printing and CNC machining form the material will be in different temperature. The temperature of a particular metal is usually related to its melting points. While 3D Printing composites and polymers have lower temperature limits than metals.

Moisture

Some filaments of 3D Printing tend to absorb moisture which will affect the entire printing process, and you may get the final parts with worse strength and toughness. Besides, there is a possibility that high humidity may cause steel to rust.

Image Source: INSTITUTION of MECHANICAL ENGINEERS

3. Economic Considerations

When it comes to cost, there are a few questions you need to ask yourself, such as when do you need the parts, how much do you need, and what is the budget on machines?

Normally, with the subtractive nature of CNC machining, parts that produced by CNC machining is faster than those of 3D Printing. The major reason is part size will not affect too much on manufacturing efficiency and time. However, in terms of software program preparations and machine setup, CNC may need much more time than 3D Printing. If the part size is small, and the part is no need of removing too much materials, 3D Printing can deliver final part to you faster.

CNC machining is the ideal method to low-medium production as programming and setup can be used repeatedly while the actual time for cutting and shaping the blank is fairly short, which means you can reduce per-unit time in the process of bulk production. When it comes to produce products with low volume, the first unit cost is relatively low, as programming (slicing) is much easier, per unit cost is not much affected by volume.

Generally, the price of 3D printers and CNC machining depends on functionality and accuracy, but 3D printer price can be much lower than CNC machines. Meanwhile, CNC machining needs trained full-time operators and programmers to ensure successful manufacturing, and maintenance cost could be high. However, when the volume is scaling, CNC machining is more cost-effective.

Image Source: RapidDirect

Overall, perfect manufacturing is non-existence and there is no technology that can do all stuff at once. The most appropriate method depends on material, production volume, machine budget, and geometric complexity, etc. If you still have no clue that which one is the best way to produce your parts, there are many online manufacturing service providers in the market nowadays, you don’t even have to own a machine yourself.

Wenext provides dedicated and versatile solutions for on-demand manufacturing, satisfying various needs from our customers. We have CNC milling, CNC turning, and multiple surface finishes for CNC machining. While 3D Printing services in Wenext include SLA, SLS, MJF, and SLM metal 3D Printing. Customers can choose the services accordingly and upload your files (STL for 3D Printing, STEP for CNC machining) on our instant quoting engine, and we will help you check the file, ensuring the files are printable. Moreover, we offer a variety of materials and post-processing choices. We strive to deliver the best services and help our customer turn creativity into reality. Email hello@wenext.com for more.

WeNext collaborated with LiYi Bionics, utilizing 3D printing technology as the core manufacturing method, to pioneer a new paradigm for the development and mass production of mechanical bionic hands.

WeNext systematically elaborates on the relevant performance characteristics of Future PA11Pro, shares the material's application in 3D printing, and compares its performance differences with PA12 material, providing a reference for printing material selection and development applications.

WeNext's new generation of FDM materials are continuously being launched. Industrial-grade FDM printing production solutions effectively assist manufacturing across various industries in achieving performance breakthroughs and functional integration.

How to build a movie camera yourself using 3D printing technology? How to perfectly replicate model car parts? WeNext, the great assistant for maker enthusiasts, tells you the answer!

WeNext collaborated with LiYi Bionics, utilizing 3D printing technology as the core manufacturing method, to pioneer a new paradigm for the development and mass production of mechanical bionic hands.

WeNext systematically elaborates on the relevant performance characteristics of Future PA11Pro, shares the material's application in 3D printing, and compares its performance differences with PA12 material, providing a reference for printing material selection and development applications.

WeNext's new generation of FDM materials are continuously being launched. Industrial-grade FDM printing production solutions effectively assist manufacturing across various industries in achieving performance breakthroughs and functional integration.

How to build a movie camera yourself using 3D printing technology? How to perfectly replicate model car parts? WeNext, the great assistant for maker enthusiasts, tells you the answer!

3D printing has become a key technological pillar for the new energy vehicle industry to achieve lightweighting, intelligence, and sustainable development, bringing fresh competitiveness to the sector's advancement.

3D printing technology is reshaping the landscape of the cultural and creative industries in application scenarios such as customized cultural product creation, film & TV IP derivative development, and game merchandise production.

3D printing technology has become a key force driving the advancement of manufacturing in the aerospace sector.

Decoding the manufacturing journey of the “Bloom” torch for the 15th National Games, WeNext broke through the bottlenecks of traditional processes through metal 3D printing technology, transforming Macro’s design concept into reality.

Wenext offers one-stop solutions ranging from rapid prototyping to professional-grade part manufacturing, providing efficient, specialized, and easily accessible manufacturing support for education and scientific research

Wenext launches an LCD printing materials application feature, interpreting the unique properties of diverse high-performance printing materials to provide reference for customers in material selection and application for LCD printing.

Wenext and Liyi Bionics join hands and, with 3D printing technology as the core manufacturing approach, create a completely new paradigm for the research, development, and mass production of mechanical bionic hands.

The integration of 3D printing has not only sped up the design process but also introduced unprecedented flexibility and innovation into the automotive industry

©2019-2025 WeNext Technology Co., Ltd. All Rights Reserved.

This website uses cookies for better personalized services. By using our websites, you agree to this use. Privacy Policy

We use cookies to improve your experience, check out Privacy Policyy.