SLA vs SLS, both 3D Printing technologies are using laser to create solid objects, learn the differences between SLA and SLS in the article.

SLA vs SLS, both use laser to create solid objects, are playing a significant role in 3D Printing technologies. However, SLA vs SLS 3D Printing create entirely different products because of the printing material, laser energy, etc. Thus, we will discover the differences between SLA and SLS in this article.

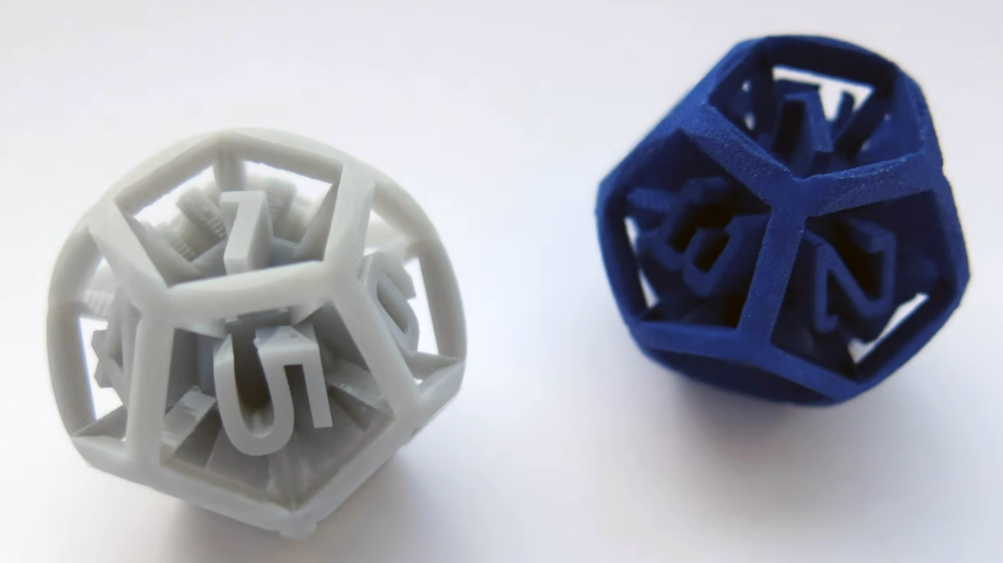

Image Source: All3DP

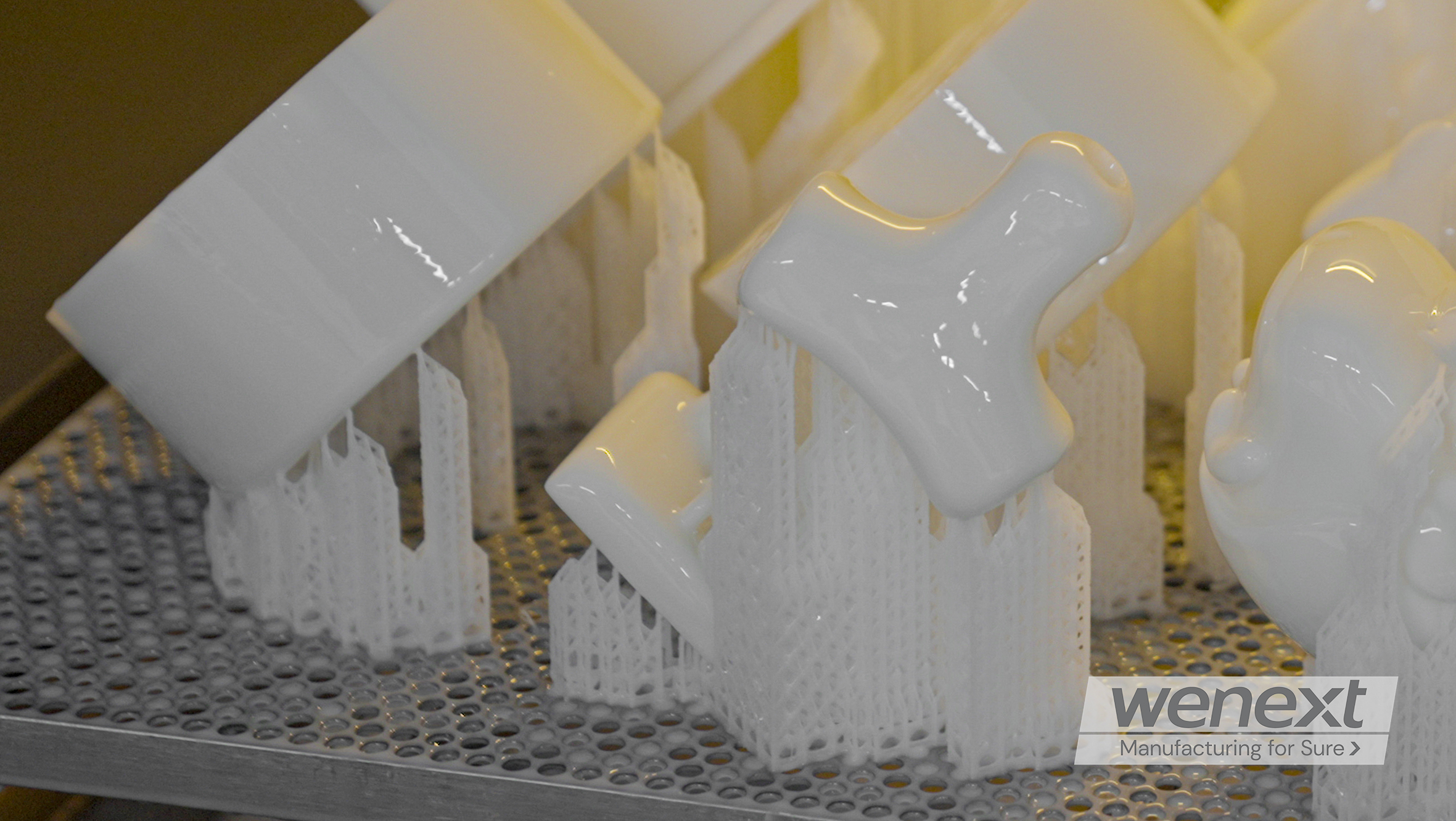

SLA, also known as stereolithography, utilizes laser to cure liquid resins and build solid objects layer by layer, is one of the earliest 3D Printing technologies. Basically, SLA 3D Printing contains three steps, preparation before printing, SLA Printer processing, and post-processing. Before printing, STL file is ensured printable and uploaded on the SLA printer, and details like thickness, angles, etc. are preset. Moving forward to SLA printer process, there are five important parts: material pool, scraper, laser, balance weight, computer-controlled mirror. By pouring enough SLA resins into the clean material pool, making sure there is no remaining resins on the scraper, the material pool is ready. While the balance weight guarantees that the material pool stays at the same level when the printing bed moves downward as one layer is finished printing. As SLA printing material is liquid resin, supports are needed during printing. When the SLA printer starts working, the computer-controlled mirror will guide the laser light to the right coordinates, and scanning and curing shapes of the 3D design. One layer is cured, printing bed goes down to a preset thickness which is normally 0.1mm; and the printer will keep curing resin until the part is built.

When printing process is done, it is necessary to lifts up the printing bed to let the solid part emerge from the material pool as there are uncured resins in it. Besides, this step helps remaining sticky resins on the parts run down. Leave the SLA prints sit for a while, then move forward to post-processing, ultra-sonic cleaning, supports removing, re-cured printed parts, sanding, sand blasting, and painting, etc.

These are the basic steps of creating SLA printed products, you can discover more about SLA 3D Printing and gain instant quotation on our website.

SLS, or selective laser sintering, is a 3D Printing technique that uses high-power laser light to sinter and fuse plastic powders together, and eventually create solid objects layer by layer. SLS 3D Printing is being able to print objects with complex geometries and structures without using supports, because the un-sintered powder can support the printed parts. Different from SLA, SLS material is thermoplastic powders, which makes SLA and SLS produce parts with vast differences. Let's see how SLS works exactly.

Starting with how SLS printer prints parts. SLS printer has a build platform, a powder bin, a recoating blade, high-energy laser, heaters, galvanometers, and a powder feeder. The first step is to preheat the build chamber and powder bin to a temperature a little below the melting pointing of SLS materials. Dispersing a thin layer of powder on the build platform by the recoating blade, then the laser scan shapes on the powder layer, sintering, heating the powder selectively, and fusing old layers and new layers together. Scanning finished, the build platform goes down to a thickness and the recoating blade will disperse a new layer of powder. The SLS printer keeps working and the entire process keeps repeating until the solid parts is created.

After printing, there is one extra process for the printed parts before unpacking, which is cooling. It takes time to cool down the build chamber, while cooling time depends parts size and amount, sometimes may up to 12 hours. Cooling process is not just because of the build chamber is in high temperature, the process protects the printed parts from warping and optimizes the mechanical properties of the printed parts as well. Unpack the SLS prints from the build chamber and clean the excess powder is the first step of SLS post-processing. Those remaining powders can be recycled and reused, which considers SLS 3D Printing is cost-effective. Besides, sand blasting, grinding, painting is options to make custom SLS products. The quality of SLS prints resembles end-use quality, and can be applied in various scenarios.

Learn more SLS 3D Printing Services on our website, or contact us at hello@wenext.com if you are interested.

Let's take a look at the direct differences between SLA and SLS prototyping.

1. Material. Printing material is the major difference between SLA and SLS. SLA prints parts with liquid resin, whereas SLS printing material is thermoplastic powder. Different material attributes create diverse products. SLA prints have smooth surface and detail finish, and SLS prints feature high strength and accuracy, but the surface is less smooth. Besides, as material is liquid, SLA printing process needs supports to print a solid object successfully, and the un-sintered SLS powder can support the printed areas so SLS doesn't need support structures and produce parts with complex geometries easily.

2. Technology. SLA and SLS are using laser to build parts, however, the power of laser is different. SLS utilizes higher energy laser so that it can sinter and fuse the plastic powder. Moreover, the door of SLS printer is smaller than SLA printer's for protection.

3. Post-processing. As mentioned above, material differences make these two 3D Printing technologies and printed parts distinguished, also including post-processing. SLA prints need time to sit so that the remaining resin can run down; SLS prints need cooling before unpacking. SLA prints is sticky and cleaning is necessary; SLS prints need to clean excess powder while unpacking.

4. Applications. SLA can create parts with smooth surface and high precision, but parts are temperature sensitive, which makes SLA prints suitable for concept validation and model display. SLS produces high quality parts that are close to end-use quality, making SLS prints suitable for rapid and functional prototyping, small batch manufacturing, and end-use production.

5. Cost. The most intuitive difference of cost is the price of SLA printer and SLS printer. SLS printer can be much more expensive than SLA printer.

Image Source: tctmagazine.com

WeNext collaborated with LiYi Bionics, utilizing 3D printing technology as the core manufacturing method, to pioneer a new paradigm for the development and mass production of mechanical bionic hands.

WeNext systematically elaborates on the relevant performance characteristics of Future PA11Pro, shares the material's application in 3D printing, and compares its performance differences with PA12 material, providing a reference for printing material selection and development applications.

WeNext's new generation of FDM materials are continuously being launched. Industrial-grade FDM printing production solutions effectively assist manufacturing across various industries in achieving performance breakthroughs and functional integration.

How to build a movie camera yourself using 3D printing technology? How to perfectly replicate model car parts? WeNext, the great assistant for maker enthusiasts, tells you the answer!

WeNext collaborated with LiYi Bionics, utilizing 3D printing technology as the core manufacturing method, to pioneer a new paradigm for the development and mass production of mechanical bionic hands.

WeNext systematically elaborates on the relevant performance characteristics of Future PA11Pro, shares the material's application in 3D printing, and compares its performance differences with PA12 material, providing a reference for printing material selection and development applications.

WeNext's new generation of FDM materials are continuously being launched. Industrial-grade FDM printing production solutions effectively assist manufacturing across various industries in achieving performance breakthroughs and functional integration.

How to build a movie camera yourself using 3D printing technology? How to perfectly replicate model car parts? WeNext, the great assistant for maker enthusiasts, tells you the answer!

3D printing has become a key technological pillar for the new energy vehicle industry to achieve lightweighting, intelligence, and sustainable development, bringing fresh competitiveness to the sector's advancement.

3D printing technology is reshaping the landscape of the cultural and creative industries in application scenarios such as customized cultural product creation, film & TV IP derivative development, and game merchandise production.

3D printing technology has become a key force driving the advancement of manufacturing in the aerospace sector.

Decoding the manufacturing journey of the “Bloom” torch for the 15th National Games, WeNext broke through the bottlenecks of traditional processes through metal 3D printing technology, transforming Macro’s design concept into reality.

Wenext offers one-stop solutions ranging from rapid prototyping to professional-grade part manufacturing, providing efficient, specialized, and easily accessible manufacturing support for education and scientific research

Wenext launches an LCD printing materials application feature, interpreting the unique properties of diverse high-performance printing materials to provide reference for customers in material selection and application for LCD printing.

Wenext and Liyi Bionics join hands and, with 3D printing technology as the core manufacturing approach, create a completely new paradigm for the research, development, and mass production of mechanical bionic hands.

The integration of 3D printing has not only sped up the design process but also introduced unprecedented flexibility and innovation into the automotive industry

©2019-2025 WeNext Technology Co., Ltd. All Rights Reserved.

This website uses cookies for better personalized services. By using our websites, you agree to this use. Privacy Policy

We use cookies to improve your experience, check out Privacy Policyy.